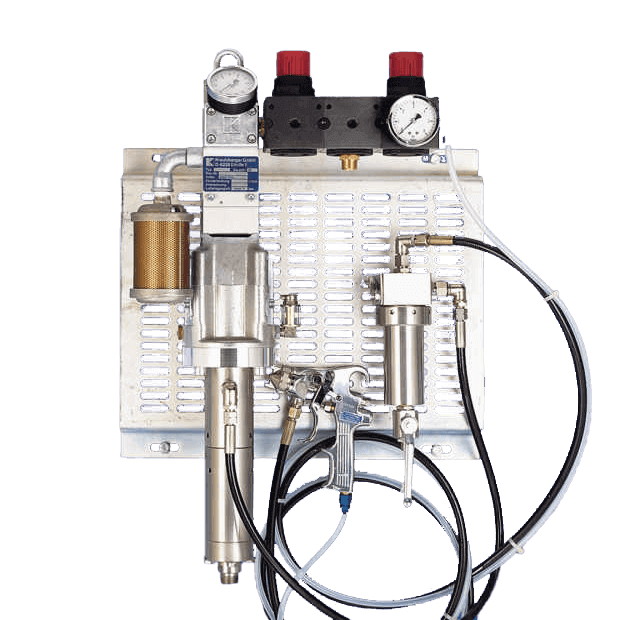

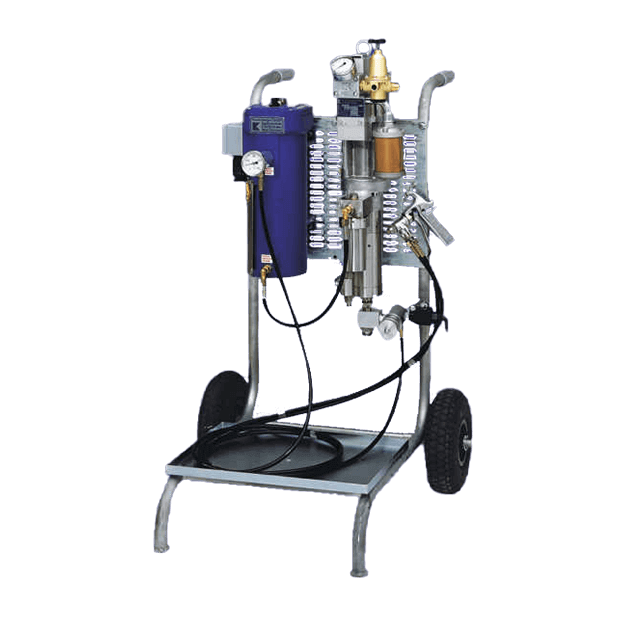

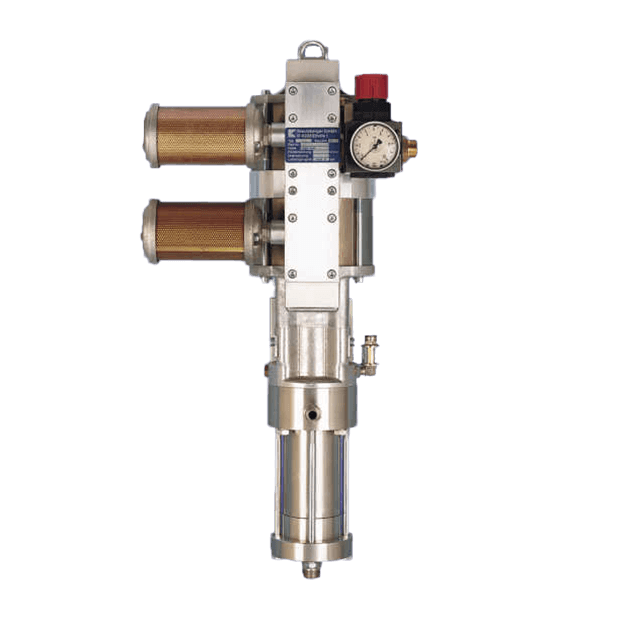

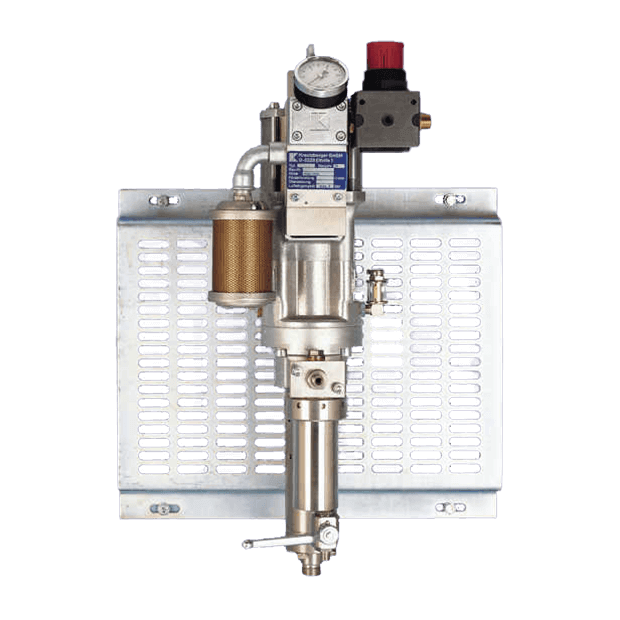

Piston pumps

During the upward stroke, the ball of the suction valve and the coating medium is sucked into the lower chamber of the working cylinder. At the same time, the ball of the pressure valve in the piston is pressed onto its seat and the medium displaced from the upper ring chamber of the working cylinder into the pressure line. During the downward stroke, the ball of the suction valve is pressed onto its seat and the ball of the pressure valve moves upward. The piston displaces half of the medium from the lower chamber of the working cylinder into the upper chamber and the other half into the pressure line. The piston rod of the air piston motor is connected to the pump piston and transmits the motion in a linear fashion. The piston motion is generated by the alternating feed of compressed air to the air motor piston and controlled by a four-way air valve.

As long as compressed air is fed into the control section via the pressure reducing valve, the thrust piston motor continues to operate until the pump has built up a sufficient hydraulic pressure in the pressure line to counterbalance the thrust of the incoming compressed air. The pump then remains in quiescent position until the hydraulic pressure begins to fall as a result, for example, of operation of the spray gun. The pump then continues to pump and maintains the dynamic equilibrium between air pressure and hydraulic pressure. The selected nozzle size and the set spraying pressure determine the stroke rate (strokes per minute) and the air consumption and thus also the spraying capacity of the pump. All pump components in contact with the medium are made of high-grade stainless steel.

Technical Center

To the technical center

Products

To the products

Contact

Contact now

Spare parts for this product

Here you can find the right spare parts for your Krautzberger product.

Your product request

Request your controller easily and conveniently by email. Fill out the following contact form and we will process your request immediately. We are looking forward to you.

There for you around the clock!

Are you seeking to improve your applications technically, modify the properties of your surfaces functionally or decoratively and optimise your processes? We support you with unrivalled quality Krautzberger products, first-class complete systems, and the development of individual solutions for your company.