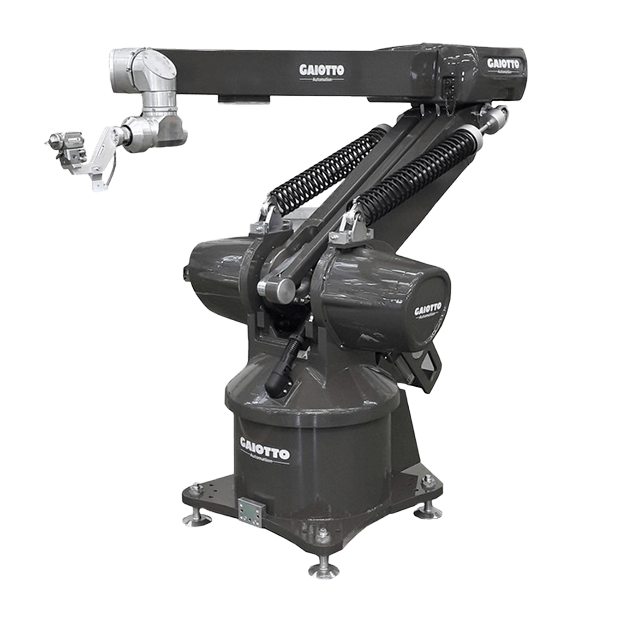

Coating robot GA 25

Mode of operation

With painting and coating industries in mind, this articulated robot uses specific kinematics and software to produce extremely effective results.

In addition to the six main axes, three interpolated axes control a wide range of motions, making challenging details more accessible.

Optionally, the device is Atmosphere Explosible (ATEX) compliant, and can therefore be used in conjunction with solvents.

The programming method operates on a self-teaching basis, where the worker first carries out the desired spray cycle by guiding the robotic arm. The motion sequence is then saved and can be repeated independently at a higher working speed. Prior experience is not necessary to facilitate this operation.

Traditional point-to-point programming is also possible, however, as well as offline programming based on CAD data. Nine hundred coating programs can be saved and recalled as required.

Furthermore, the robot is suitable for connecting to a floor or ceiling conveyor, and other feeding devices.

Technical data

Number of axes: 6

Working radius: 2465 mm

Weight: 550 kg

Nominal load at the wrist: 6 kg

Special features

• Self-teaching process

• Ex-protection option

(ATEX version)

• Also suitable for small series

• No PC knowledge required

Technical Center

To the technical center

Products

To the products

Contact

Contact now

Spare parts for this product

Here you can find the right spare parts for your Krautzberger product.

Your product request

Request your controller easily and conveniently by email. Fill out the following contact form and we will process your request immediately. We are looking forward to you.

There for you around the clock!

Are you seeking to improve your applications technically, modify the properties of your surfaces functionally or decoratively and optimise your processes? We support you with unrivalled quality Krautzberger products, first-class complete systems, and the development of individual solutions for your company.