Coat large area in shortest time

Adhesive spraying is used in many industries and applications to join materials together quickly and efficiently. It is a quick and easy way of bonding, making it suitable for coating large areas or reaching small and particularly hard-to-reach places. Adhesive application is used in many other industries. At Krautzberger, we are familiar with the application of adhesives in a wide range of industries. In addition to the automotive industry, our expertise extend to the food industry, the pharmaceutical industry, the supplier industry, and the glass, ceramics, wood, plastics and leather industries.

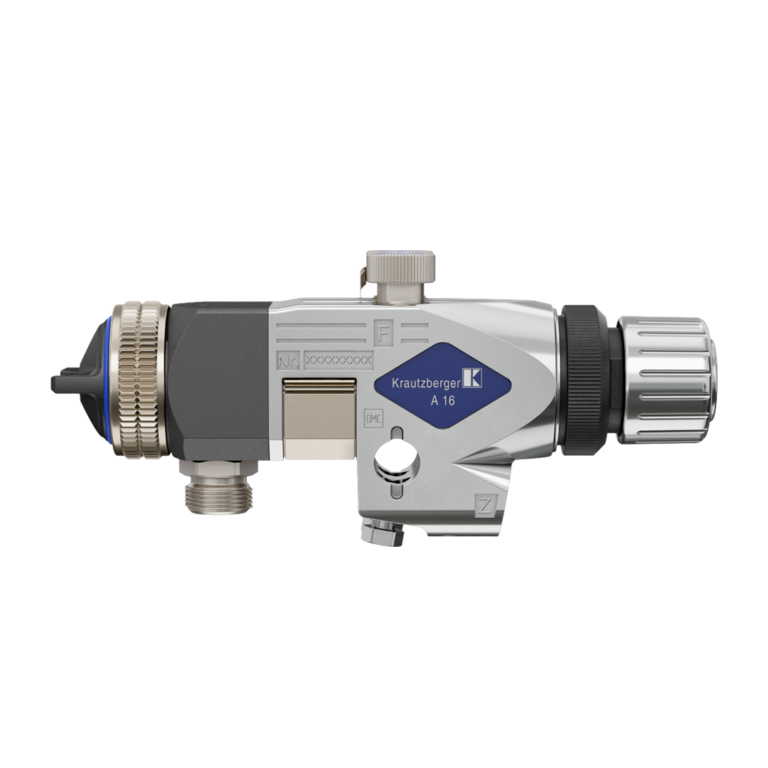

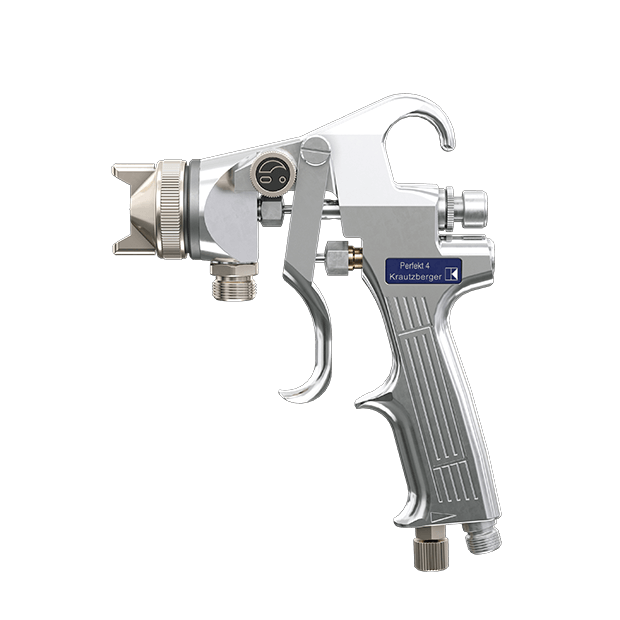

Adhesive spraying is done with a spray gun, which allows fine application of the adhesive. For Krautzberger, it is not initially important whether the adhesive used by our customers is water-based or solvent-based. We are very familiar with both areas and know what our customers require. A variety of adhesives can even be used depending on the application. This includes adhesives with different properties, such as high adhesive strength, flexibility or water resistance. At Krautzberger, we have a broad portfolio of manual and automatic spray guns for this reason. Thanks to our wide range of variants and with the help of our XLINE and the associated air nozzle variety, we cover our customers' requirements.

One advantage of spraying adhesive is that it is a very clean way of bonding. There are no smeared or uneven spots as there’s no need to use a brush to apply the adhesive. The adhesive can also be applied exactly where it is needed, which saves time and material. A further advantage is that spraying adhesive can be done quickly. A large area can be coated in a very short space of time, which is a significant advantage for manufacturing companies. It is also easy to operate and can be used by untrained personnel.

When spraying adhesive, some important aspects need to be considered to achieve an optimal result:

- Select the right adhesive: The adhesive chosen should be appropriate for the type of materials to be joined and the ambient conditions.

- Prepare the surfaces: The surfaces to be joined need to be clean, dry, and free of grease.

- Spray gun: It is important to choose a suitable spray gun that allows you to achieve the desired purpose. The spray gun should be easy to use and be precise and robust.

- Pressure regulation: Precise pressure regulation is important to ensure an even distribution of adhesive and avoid unnecessary waste.

At Krautzberger, with the help of our material pressure vessels, diaphragm pumps, and fluid pressure regulators, we can always deliver the desired amount of material to the spray gun. Only with optimum precision in this area will you achieve the desired result in your painting process. We can advise you on adhesive conveyance at any time and plan your painting process. Adhesive application is an important area for our customers and their applications. So if you’re looking for a suitable glue gun or need any help with adhesive conveyance, please get in touch with us. Krautzberger offers everything you need for your adhesive application. Manual and automatic glue guns as well as full coverage of material supply and adhesive extraction needs.

Successful adhesive applications put into practice by Krautzberger:

- Application of adhesive to shoe soles to bond them to the shoe

- Spraying of 2K adhesive, mixing in spray jet

- Application of adhesive for automotive interiors

- Spraying of laminating adhesive in the automotive industry

- Spraying of laminating adhesives in the supplier industry

- Bonding of foam and fabric to produce seats

- Production and bonding with white glue of partition walls

- Dosing of adhesive in the engine area

There for you around the clock!

Are you seeking to improve your applications technically, modify the properties of your surfaces functionally or decoratively and optimise your processes? We support you with unrivalled quality Krautzberger products, first-class complete systems, and the development of individual solutions for your company.